Semi Automatic Paperboard Flute Laminator Machine High Quality Cartonbox Laminating Machine

Overview Semi Automatic Flute Laminator Machine Product Description Major feature:The high speed, high accurate flute la

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | TM-1300 TM-1400 TM-1500 TM-1600 |

| Machine Type | Semi Automatic |

| Transport Package | Plastic |

| Specification | 3500kg |

| Trademark | JIALONG |

| Origin | China Hebei |

| HS Code | 84413090 |

| Production Capacity | 30sets/Month |

Product Description

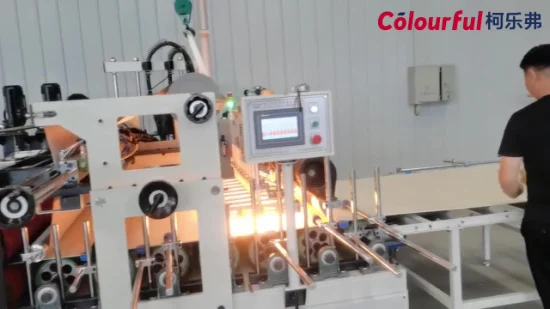

Semi Automatic Flute Laminator Machine

Major feature:The high speed, high accurate flute laminate which developed by our Company is the most advanced in our country.

This machine operation is stable, joint accurate, easy operation, need not skilled workers.

This machine is used for making Print paper and bottom paper(card paper, corrugated paper) match together accurately, then the paper level off, and high precision.

1. Feeding of high table, automatic feeding for bottom sheet, elastic front register, simple operation.

2. just need one person to feed the paper. It has low request to paper, suitable for laminating paperboard to bottom paperboard, ABCDE Flute corrugated cardboard. Even filmed paper can be laminated.

3. Top sheet forwarded by manual on high table and the sheet can be piled up to 1.8m.

4. Bottom sheet is automatically fed; the two sheets are piled freely; High efficiency

5. Advanced elastic front register is used for location, high register precision, bottom paper will never exceed. When laminating, it is very easy to make top paper and bottom paper alignment, or top sheet exceeded.

6. Fully automatic glue supply system: glue will be automatically supplied during lamination, and recovered, avoiding glue wasted.

7. Scientific design for linear speed of metering roller, avoiding glue thrown when high-speed running.

7. The whole machine adopts PLC control system, compared with other time-delay device or middle relay control, the bottom paper is transferred more precise and stable, furthermore, speed is greatly increased, and circiut breakdown can automatically display and alarm.

8. Clean the lower roller in gluing section by blade with circulated water, complete cleaning, convenient to replace the blade

9. Floating movable pressing section is adopted to make the laminated paperboard smooth. This section can be moved front and back to take in paper conveniently.

10. Gear rach is used to control the lift of water tray, which is easily taken out for cleaning

| model | TM-1300 | TM-1400 | TM-1500 | TM-1600 |

| Max size of cover face | 1300x1100mm | 1400X1250mm | 1500X1250mm | 1600X1250mm |

| Min size of cover face | 360x360mm | 360x360mm | 360x360mm | 360x360mm |

| Economic speed | 0-100piece/min | 0-100piece/min | 0-100piece/min | 0-100piece/min |

| precision | ≤±1mm | ≤±1mm | ≤±1mm | ≤±1mm |

| power | 6kw | 6kw | 6kw | 6kw |

| size | 8.8x1.95x1.5m | 8.8x2.05x1.5m | 8.8x2.15x1.5m | 8.8x2.25x1.5m |

| weight | 3T | 3T | 3.5T | 3.5T |

Jialong Packaging Machinery Co.,Ltd is a academician of Chinese PackagingTechnic Association.Our companyspecializes in discovery, development and production of paper boardproduction line ,automatic flexo ink printing slotting die cutting machine, automatic flexoink printingslotting machine, automatic flexoinkprinting die cuttingmachine,semi-autoflexo ink printing slotting machine, semi-auto water ink printing die cuttingmachine ,slicingcardboardand pressing line machine, rotary die cutting machine, slottingmachine, carton stapler, casegluing machine, impressing machine and other relevantpackaging machinery.Many years before, our company considers Quality is first, Honesty is root" as ourprincipal,to meet customers' demand is our target. We can supply from machine designto after-sale allservice with high quality and professional technique.We would like to cooperate with friend from every countries sincerely, and we willwork hard to create the future of package together.

1

Q: Are you a factory or trading company?

A: We are a manufacture which is specialized in the production of various kind of carton equipments.(with export license)

2

Q: Where is your factory located? How can I visit here?

A: Our factory is located in Dongguang Town Cangzhou City Hebei Provience China. We can pick you up if you need, welcome to visit our factory.

3

Q: What are your products?

A: We are specialized in producing 3ply, 5ply, 7ply corrugated cardboard production line, high speed printing machine, ordinary

printing machine, single facer rotary die cutter and other corrugated cardboard production equipments.

4

Q: How does your factory do regarding quality controlling?

A: Over the years our company take "the quality first" "integrity-based" corporate purpose always meet users' requirements as our

sole purpose, providing the products with excellent quality, professional technology. always attach great importance to quality

controlling from the very beginning to the very end .

a.All raw material we used are environmental-friendly

b.skillful workers care every details in handling the producing and packing process

c.uality control department specially responsible for quality in each process.

5

Q: How is the evaluation of the products?

A: Products are distributed in Russia, the Middle East, Africa, Southeast Asia,

EU and other countries and throughout the country. Product quality and enterprise reputation get the high praise at home and aboard.

Eve

Jialong Packaging Machinery Co., Ltd

Tel:0086-317-7800200

Fax:0086-317-7897598

Related Products