Paper Carton Making Automatic Flute Laminator for Cardboard Creasing and Box Platform Flat Bed Die Cutting Flute Laminator

Overview Product Description Paper Carton Making Automatic Flute Laminator for Cardboard Creasing and Box Platform Flat

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | KD-GSF |

| Membrane Material | Paper |

| Performance | Flute Lamination |

| Laminating Material | Corrugated Paperboard |

| Max Paper Size | 1300*1100mm |

| Transport Package | Wrapped in PE Film or Cotton Cloth, Then Packed by |

| Specification | Depends on paper size |

| Trademark | KADING |

| Origin | Dongguang, Cangzhou, Hebei |

| HS Code | 84393000 |

| Production Capacity | 100sets/Year |

Product Description

Product Description

Paper Carton Making Automatic Flute Laminator for Cardboard Creasing and Box Platform Flat Bed Die Cutting Flute Laminator

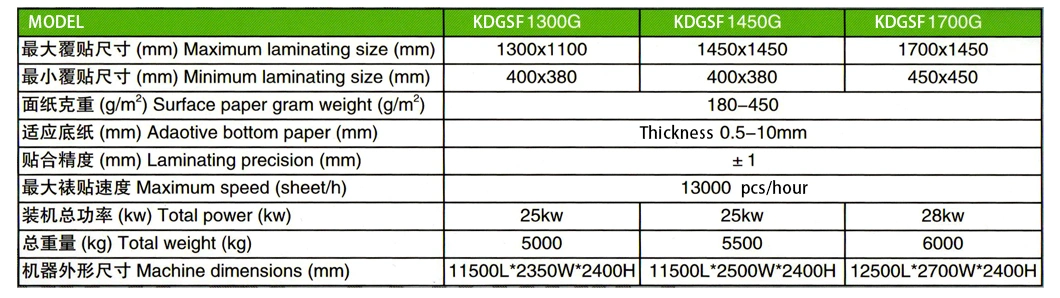

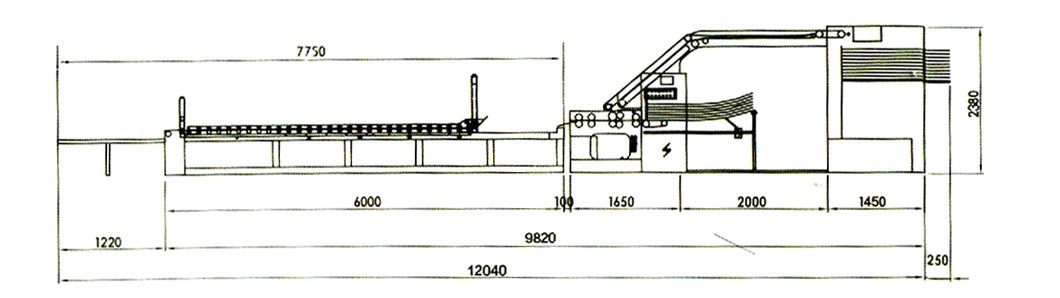

1. Computerized high-speed lamination, 13,000 sheets per hour (paper within 700mm)2. The paper feeding machine adopts a linear guide rail and a feeder head with a high-speed conjugate cam structure to ensure stable and accurate paper feeding at high speed.3. Glue coating device: high-precision coating conveying with automatic page control of paper and glue wheel side stop structure, up to running without overflowing glue and can adjust the small backflow of glue.4. Sensing and compensation alignment device: use multiple sets of electric eyes to know the relative position of the bottom line, and use servo motors on both sides of the paper to do independent transmission to compensate the upper and lower paper alignment, which is accurate and smooth.5. Full-featured electronic control system: It uses man-machine interface and PLC program light display, which can automatically detect abnormal operation status and display work records.Product Parameters

Paper Carton Making Automatic Flute Laminator for Cardboard Creasing and Box Platform Flat Bed Die Cutting Flute Laminator

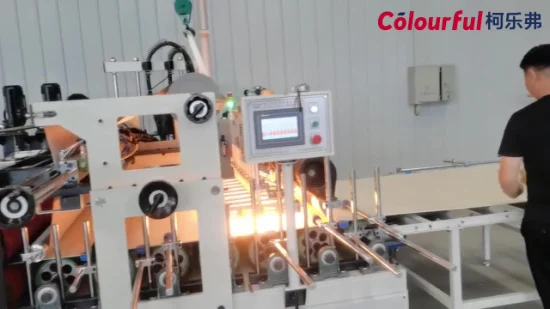

Detailed Photos

Cangzhou Kading Carton Machinery Manufacturing Co.,Ltd was founded in 2004 and is located in Dongguang County, Cangzhou City, Hebei Province. We are a manufacturing enterprise that produces carton making machinery.Our company's self-produced product lines include carton printing machines, carton die-cutting machines, and carton slotting machines; our advantageous products include Carton stitching machines, Folder gluer machines, Flute laminating machines, Single facer machines, etc. After nearly twenty years of sales and production experience, our product supply chain is already very mature, so we can help customers one-stop purchasing.In addition to our own foreign trade business, our factory also cooperates with many trading companies, so our products are exported to dozens of countries such as the Middle East, Africa, Southeast Asia, and the European Union, and are well received by the majority. There are also many brand&branded manufacturers among our customers. You are welcome to cooperate with us~!

Q: Are you a factory or a trading company?

A: We are a direct manufacturer that is located in Dongguang county, Cangzhou city. Welcome to visit our factory! We can also have video call if you'd like an online factory tour

Q: How do you ensure your quality?

A: 1. Trustworthy and long-term cooperative raw material suppliers;2. Skilled&experienced engineer&workers;3. Mature QC system;4. Specially-assigned merchandiser;5. Advanced production workshop

Q: How about your after-sale service?

A: 1. Special after-sale team will be 24/7 online;2. Can guide the installation door-to-door;3. One-year warranty for spare parts.

Related Products

-

![Cosmetic/Gift/Milk/Electrical/Medicine/Carton Box Folder Gluer Machine]()

Cosmetic/Gift/Milk/Electrical/Medicine/Carton Box Folder Gluer Machine

-

![Fully Automatic Thermal Film Laminator Machine [YZFM800dB]]()

Fully Automatic Thermal Film Laminator Machine [YZFM800dB]

-

![Leadworld Carton Erector Machine Customized Fully Automatic Erecting Machine for Carton Case]()

Leadworld Carton Erector Machine Customized Fully Automatic Erecting Machine for Carton Case

-

![Flatbed Digital Die Free Automatic Vibrating Knife Gasket Making Machine Asbestos Non]()

Flatbed Digital Die Free Automatic Vibrating Knife Gasket Making Machine Asbestos Non

![Fully Automatic Thermal Film Laminator Machine [YZFM800dB]](/uploads/s/38c4723b418642db8f4eed614aa305fb.webp)