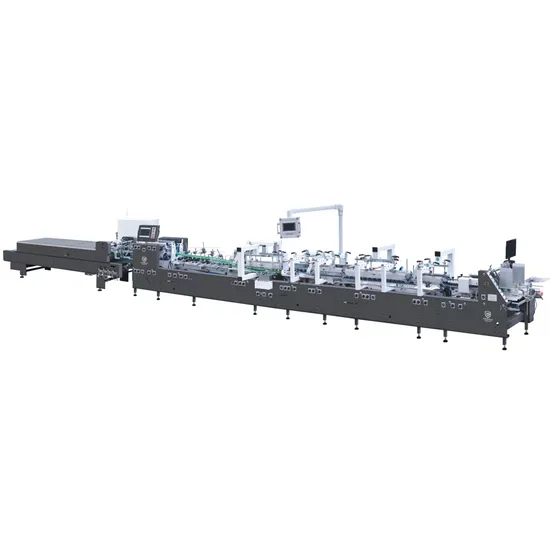

Hot Product Ci Type High Speed 4 Colour 6 Colour Flexo Printing Machine Kraft Paper Roll to Roll Printing

Overview Feature: MACHINE TYPE:CENTRAL IMPRESSION TYPE,FILM SUPPORTED BY THE BIG DURM,NEVER LEAVING BETWEEN COLORS,SO RE

Send your inquiryDESCRIPTION

- Overview

- Product Description

- Product Parameters

- Company Profile

- Packaging & Shipping

- Certifications

- FAQ

- Our Exhibition

- Customer Feedback

Basic Info.

| Model NO. | 600-1600 |

| Printing Page | Double Faced |

| Printing Color | 6 Colors |

| Anilox Roller | Ceramic Anilox Roller |

| Dryer | IR |

| Type | Ink Jet |

| Embossing Structure | Rotary Letterpress |

| Structure | Satellite |

| Application | Flexible Packaging Printing |

| Automatic Grade | Automatic |

| Printing Speed | 150meter/Min |

| Printing Width | 1200mm |

| Printing Length | 380-1200mm |

| Voltage | 3p, 380V 50Hz |

| Plate Thickness | 1.7mm |

| Transport Package | Plastic Film |

| Specification | 1200 |

| Trademark | smile |

| Origin | Zhejiang Wenzhou |

| HS Code | 8443160090 |

| Production Capacity | 500 |

Product Description

Feature:

Main Parameters:

Q: Are you manufacturer or trading company? A:We are the manufacturer and have our own workers and factories.

Q:How long is the warranty period?

A: All of our products have 2 year warranty and whole life maintance

Q: What's the main market of your company?

A: We have customers all over the world

Q: What's your delivery time and payment Terms?

A: Normally,it need about 10-30 days.The exact time depends on your quantity.The payment terms always 30% deposits,70% to be paid before shipment.

Q: What package do you use for the product? A:Be Coated with anti-corrosion oil, and covered with plastic film, wooden box package need extra cost.

Q: Does your factory provide installation service? A:Our engineer can go to customer factory to installation . buyer should prepare materials used to testing the machine in advance and should be responsible for the cost of supplier's technician, including round air tickets, visa cost, accommodation and salary 120-150USD/Day per person since the day start out until the day arriving at factory.

Q: Can we visit your machine operation in your factory?

A: Welcome to you go to our factory to see the machine operation.

Q: Where's your factory located? How can we visit there?

A: We are in Zhixin industry Zone, Ruian City,Zhejiang province,China.

You can by air to Wenzhou airport and by High-speed train to Rui'an Station

Product Description

Product Parameters

| 1)MAIN PARAMETER | |

| MACHINE MODEL | CI61000 |

| MAX.MATERIAL WIDTH | 1000mm |

| MAX.PRINTNIG WIDTH | 950mm |

| SUITABLE FOR MATERIAL | PVC:10~120μm,OPP:10~100μm,BOPP:10~100μm,PE:15~150μm,NY:10~120μm,PET:10~100μm,CPP:10~100μm AND SO ON |

| PRINTING COLORS | 6COLORS |

| PRINTING LENGTH | 380-1200mm |

| MACHINE SPEED | 200M/MIN |

| PRINTING SPEED | 150M/MIN |

| PLATE THICKNESS | 1.7mm |

| TAPE THICKNESS | 0.38mm |

| VOLTAGE | 3P 380V 50HZ |

| 2) UNWINDER UNIT | |

| ROLL WIDTH | 1000mm |

| PRINTING WIDTH | 950mm |

| MAX.RAW DIAMETER | 1000mm( CAN MAKE ACCORDING TO CLIENT'S REQUEST) |

| UNWINDER EPC | SERVO EPC SYSTEM |

| UNWINDING WAY | POWDER AUTO TENSION CONTROL, PNEUMATIC TYPE |

| AIR SHAFT | 1PC |

| 3)TRACTION UNIT | |

| ZONE | 2 |

| TRACTION PRESSING WHEEL | CYLINDER TYPE |

| TRACTION DRIVING | 8M TIMING BELT |

| 4)PRINTING UNIT | |

| CENTRAL DURM DIA.R | 1200mm |

| ANILOX ROLLER | CERAMIC ANILOX ROLL 6PCS |

| PRINTING CYLINDER | STANDRAD(LESS THAN 400MM,ACCORDING TO CLIENT REQUEST,CAN EXTRA TO PAY FOR 380-1200MM) |

| CHAMBER DOCTOR BLADE | 6PCS |

| DRIVING TYPE | 8M TIMING BELT+HIGH PRECISION HELICAL GEAR DRIVING |

| ADJUSTING OF REGISTER | ELECTRIC MOTOR |

| PRINTING PRECISION | +-0.1mm |

| ROLLER ADJUSTING | HYDRAULIC ENTRY AND EXIT EDITION |

| CAMERA | 1pc |

| PLC | 1 pc |

| 5)HEATING AND DRYING UNIT | |

| TYPE OF HEATING AND DRYING | ELECTRIC TYPE |

| HEATING POWER | 60kw |

| FANS | 2.2KW*2pcs, |

| 6)ELECTRIC PARTS | |

| MAIN MOTOR | 11KW |

| INK MOTOR WITH FAN | 6pcs |

| VERTICAL REGISTER MOOTR | 6pcs |

| HORIZONTAL REGISTER MOTOR | 6pcs |

| 7)REWIND UNIT | |

| ROLLER WIDTH | 1000mm |

| MAX.REWINDER DIA. | 1000mm |

| REWINDER TYPE | MOTOR REWINDING AND PNEUMATIC TYPE |

| REWINDER SHAFT | AIR SHAFT: 1PC |

Pneumatic unwind&rewind, motor winding: No manual loading and unloading, save time to improve work efficiency76mm diameter for unwinder and rewinder, which is easy to change rolls

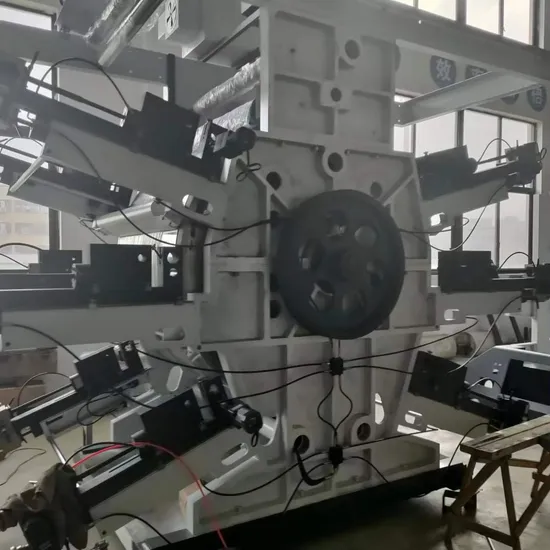

Central Drum

Camera+touch screen:Inspect the printing quality and printing precision

Drying until: Large oven, Circulation air drying

Ceramic anilox roller: Make the amount of ink more delicate,wear-resistant and durable Chamber doctor blade:Squeeze the ink evenly on the ceramic roller

Ink pump: automatic pneumatic ink,no need to put on the ink by manual

Separate Motor for ink roller:It will automatic running when machine is stop, and it can keep the ink running. No dry for ink

Printing cylinder:Perimeter 380-1200mm Adopt new chrome plating technology,rustproof and durable

printed film photo

Company Profile

Packaging & Shipping

Certifications

FAQ

Our Exhibition

Customer Feedback

Related Products