Gd

1.Port of departure: NINGBO OR SHANGHAI CHINA2.Port of destination: 3.Packing: Export-standard and sea-worthy steel case

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | GD-900 |

| Packaging | Cartons |

| Transport Package | Export-Standard and Sea-Worthy Steel Case |

| Specification | 12500 x1400 x 1400mm |

Product Description

1.Port of departure: NINGBO OR SHANGHAI CHINA2.Port of destination: 3.Packing: Export-standard and sea-worthy steel case.4.Shipping Mark: to be determined at customers' option.5.Terms of payment: 30% T/T Deposit, the balance before shipment6.Delivery time: Within 30-40 working days after received the deposit7.Quality Guarantee: 1 year, the seller guarantee the machines are 100% new. The above clause is ONLY effective under the machine is being properly used , any artificial misuse or destroy prepensely is not within the limit of Quality Guarantee.The machine belt is not within the limit of Quality Guarantee.8.Supplementary Condition: If the buyer need seller`s engineer to go to his factory to help install and test the machine ,please be kindly bear their visa ,go and return tickets, lodging and eating ,salary ( USD50/day).9.validity of offer :30day10. description as next page

Feature introduction

Transmission

Equipped with feeding paper inspection device.

Equipped with impacting device to press the paper after accounting and make it easy to pack paper.

PLC touchscreen

The machine adapt touchscreen adjustment,

fast to adjust

OPTION:

Video Surveillance (TV)

More convenient and efficient to monitoring the operation of each part on the machine

Samples

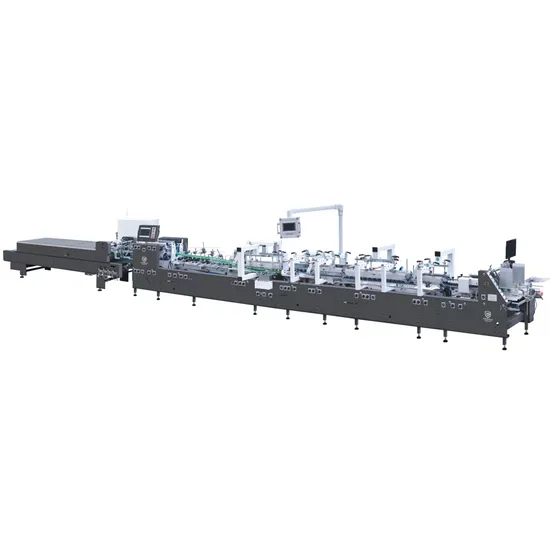

| Name | GD-900 Automatic High Speed Pre-fold & Lock Bottom Folder Gluer |

| Model | GD-900 |

| Paper Material | Cardboard 200-800g, E-flute/F-flute |

| Max. Liner speed | Max. 280 meter/minute |

| Feeding way | Automatically and continuously feeding |

| Way of folding | Fold 1 and fold 3 are 180°and 135°,Fold 2 and fold 4 are 180°, Bottom folded and glued |

| Glue Material | Water-base cold glue |

| Electric power | 7.5KW 380V 50HZ 3P |

| Weight | 3550KG |

| Over dimension | 12500 x1400 x 1400mm |

| Descriptions: | |

| This machine is specially used for paperboard shaping and adhesive processing after cutting horizontally. Its universality is strong and suitable scope is wide, which can fold and paste various straight seaming box and bottom edging box.It is widely used in food, medicine, cosmetics, stationery and other ordinary cartons, process and glue for all kinds of bottom-locked cartons.Pre-fold section is applied to auto packaging, fold 1 and fold 3 of all cartons can reach 180° and 135° ,perfectly combing the requirements of auto packaging together. | |

| Feeding 6pcs Adjustable feeding belts to ensure easy adjustment, stable and smoothly feeding. Continuously Variable Speeder to ensure feeding internal and stable transmission. One-touch Pneumatic knife, easy for the adjustment of feeding belts. |

|

| Pre-fold Double-board structure with a set of pre-folding knife. Pre-fold angle is 180°and 135°, especially suitable for small but high cartons, more satisfactory while rapid prototyping |

| Bottom-lock 3-board tracking structure, upper gluer can make bottom-locked box automatic gluing and forming, can be used for the special-shaped cartons. The entire bottom-lock part is installed in a reversible bracket, substantially reduce the swap adjustment time of bottom-fold box and the other types of box. Bottom-folding speed is 50-200 pcs per min, stable and reliable. | |

| Folding Lengthened folding to avoid the unevenness while the rapid forming of cartons and make it come to perfection. | |

| Full pressing 2-board structure Two modes for pressing belt speeding: Auto: set distance between boxes, pressing belt speed is the same as the machine, belt removes while sensor detect it. Manual: pressing belt conveys in a fixed speed and machine speed will not put any effect on it. With counting device to count the finished boxes to match with boxes regulating, easy to count and pack. |

| Lock bottom carton type and folded box size: | |||

| Model | GD-900 | GD-900 | |

| Paper | Cardboard | E/F Corrugated | |

| A | 150-600mm | 150-600mm | |

| B | 200-850mm | 200-850mm | |

| C | Min:30mm | Min:30mm | |

| D | Min:70mm | Min:70mm | |

| E | Min:30mm | Min:30mm | |

| F | Min:80mm | Min:80mm | |

| Common box type and size: | |||

| Model | GD-900 | GD-900 | |

| Paper | Cardboard | E/F Corrugated | |

| A | 150-700mm | 150-700mm | |

| B | 120-850mm | 180-850mm | |

| C | Min:10mm | Min:10mm | |

| D | Min:70mm | Min:80mm | |

| F | Min:80mm | Min:80mm | |

| Two-side gluing box type and size: | ||

| Model | GD-900 | |

| A | 100-550mm | |

| B | 100-800mm | |

| C | 70-600mm | |

| D | 10-200mm | |

| Pop corn box type and size: | ||

| Model | GD-900 | |

| A | 150-600mm | |

| B | 180-850mm | |

| C(min) | 40mm | |

| D(min) | 35mm | |

| F(min) | 20mm | |

| Note:Options customized on user order the cold glue guns system | ||

| CD box type and size: | ||

| Model | GD-900 | |

| A | 200-850mm | |

| B | 65-680mm | |

| C | Min:12mm | |

| Note:CD box device optional | ||

| French fries box type and size: | ||

| Model | GD-900 | |

| A | 240-350mm | |

| B | 190-250mm | |

| C | 100-130mm | |

| D | 85-110mm | |

| Note:Options customized on user order the cold glue guns system CD box device optional | ||

Related Products