Automatic Case Carton Master Box Packaging Machine/Case Erector Erecting /Forming/Filling/Sealing Machine for Packaging Line

Overview Detailed Photos Machine Picture: Product Description Machine Description: Automatic Case Packaging Line is made

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | KX-600 |

| Driven Type | Electric |

| Material Type | Food, Cosmetic, Medicine, Daily Necessities etc. |

| Packaging | Cartons |

| Packaging Material | Paper |

| Condition | New |

| Usage | Case Opening, Filling and Sealing |

| Model Number | Kx-600 |

| Transport Package | Export-Standard and Sea-Worthy Wooden Case |

| Trademark | Kaixiang |

| Origin | Zhejiang, China |

| Production Capacity | 50 Sets/Month |

Product Description

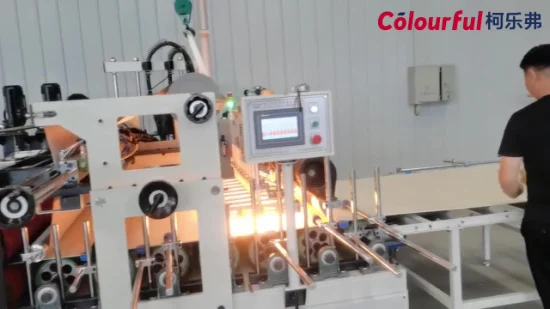

Detailed PhotosMachine Picture:

Machine Description:

Automatic Case Packaging Line is made from three parts: Case Erecting Machine, Case Filling Machine and Case Sealing Machine(Conveyor Belt).It settled down the old package style which always need manual operating in the packing procedures, can save plenty of time and space. It's high efficient in working and complete the packaging tasks stably, it would be high efficient working combine with the industry robots together.

Main Technical Parameters:

| Case Erecting Machine | |

| Carton Width | 150-400mm |

| Carton Height | 100-350mm |

| Carton Length | 200-450mm |

| Overall Dimension | L2000mm×W1900mm×H1450mm |

| Speed | 20m/min |

| Power Supply | 220V/380V 56/60HZ |

| Weight | 400KG |

| Case Filling Machine | |

| Carton Width | 150-400mm |

| Carton Height | 100-350mm |

| Carton Length | 200-450mm |

| Overall Dimension | L2000mm×W1900mm×H1450mm |

| Speed | 20m/min |

| Power Supply | 220V/380V 56/60HZ |

| Weight | 400KG |

| Case Filling Machine | |

| Carton Width | 150-500mm |

| Carton Height | 150-575mm |

| Carton Length | 500-600mm |

| Overall Dimension | L1830mm×W835mm×H1640mm |

| Sealing Speed | 20m/min |

| Power Supply | 220V/380V 56/60HZ |

| Weight | 150KG |

Company Information:

Packing & Shipping:

FAQ

FAQ:1. How long will your engineer reach our factory?Within one week after machine arrival your factory.2. How many days will you finish installing ?We will finish installation and training within 15days.3. What should we charge for your engineer?You should charge for the cost of our engineer's visa , air tickets, hotel, food ,and also their salary 80USD one day per person.4. How long is your machine's warranty period?All our machines have one year guarantee, starting from finished installation.5. How could we do after one year warranty period?We also can do service for you, but you need pay salary for our technician 80USD/day.6. How could we do if the parts broken within warranty? We would express the free replacement parts during the warranty date.7. Does your engineer understand English? Our engineer understand a little English. All our engineers have more than five years machine installation experience. In addition, they can use body language to communicate with customer.8. Can you help us find any engineer in our location? Of course, we will check and inform you as soon as possible.9. How do we solve the machine problem after your engineer leaving? Generally speaking, there will be no problem after finish installing. In case you have any problem, you can contact with our sales at any time. Our engineer will take a solution video according your description.10. How many worker do we need running those machines?Usually two or three people is ok. If it is manual feeding, more people are needed, mainly according to your production capacity.

Related Products

-

![Rolam Fully Automatic Simple Straight Line Paper Carton 4 6 Corner Box Folding Gluing Machine 400m/Min Pre]()

Rolam Fully Automatic Simple Straight Line Paper Carton 4 6 Corner Box Folding Gluing Machine 400m/Min Pre

-

![Functional Small Biscuit Making Machine/Machine Biscuit/Biscuit Cookie Machine]()

Functional Small Biscuit Making Machine/Machine Biscuit/Biscuit Cookie Machine

-

![Factory Price Automatic Laminating Machine Thermal Film Laminator for Pet PE OPP Material]()

Factory Price Automatic Laminating Machine Thermal Film Laminator for Pet PE OPP Material

-

![Vertical Double Station Carton Erecting Machine Burger Box Machine]()

Vertical Double Station Carton Erecting Machine Burger Box Machine