1450*1300mm High Precision Automatic Flute Laminator for Packaging

1. Component Ecoo 1450 automatic flute laminator mainly consists of six parts: automatic face paper feeding section, fac

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | Ecoo 1450 |

| Bottom Paper | a.B.C.D.E Flute |

| Front Lay Laminating Precision (mm) | +/-1.5 |

| Transport Package | Standard Exporting Package: Polywood Carton |

| Specification | 12000x2300x2950mm |

| Trademark | EcooGraphix |

| Origin | China |

| Production Capacity | 500sets/Year |

Product Description

1. Component

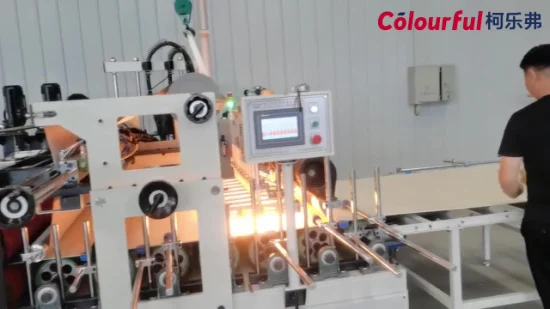

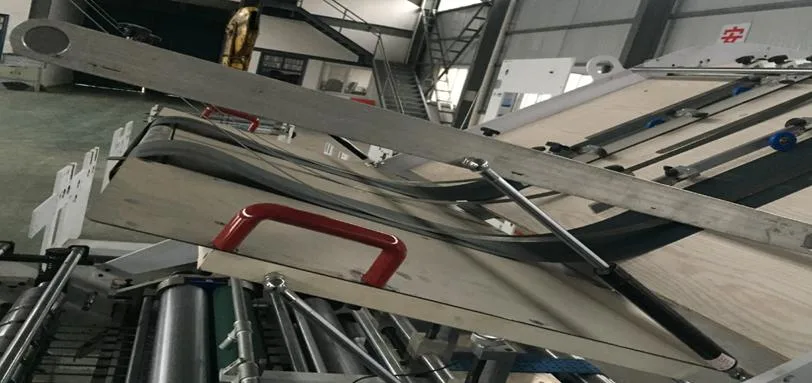

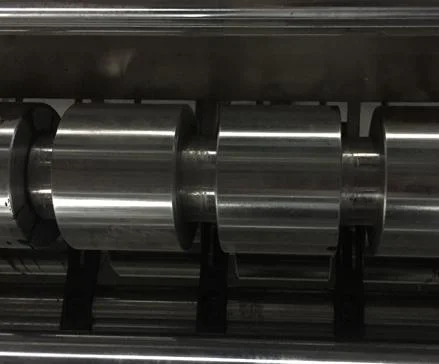

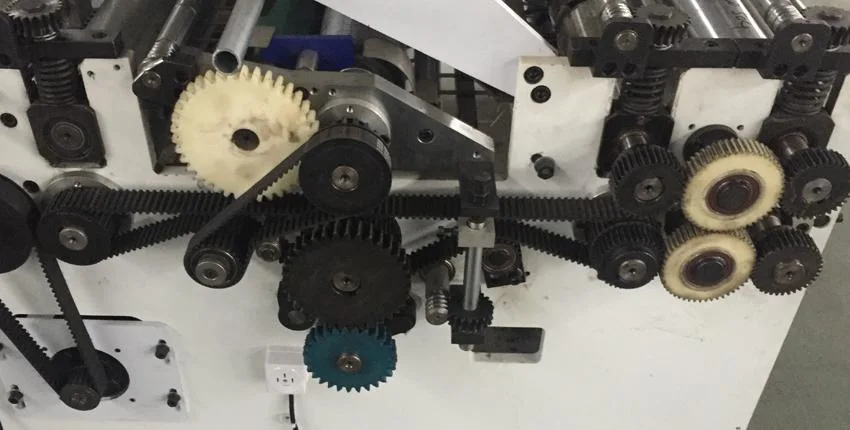

Ecoo 1450 automatic flute laminator mainly consists of six parts: automatic face paper feeding section, face paper conveying section, automatic bottom paper conveying section, cyclic gluing section, positioning and pre-pressing section and pressing section. It suits to laminate the printed paper to the corrugated board(3ply), with features of high precision and high speed. It is the ideal laminating machine for all kinds of packaging company.

3. Specification

| Model | Ecoo 1450 |

| Max. Paper size(mm) | 1450×1300 |

| Min. Paper size(mm) | 400×400 |

| Thickness of face paper(g/m2) | 150-500 |

| Bottom paper | A.B.C.D.E flute |

| Front lay laminating precision (mm) | ±1.5 |

| Mechanical speed (m/min) | 110 |

| Laminating efficiency (sheets/h) | 0-6000 |

| Power supply | 380V 3P 5W 50Hz |

| Dimension ( mm L*W*H) | 12000×2300×2950 |

| Weight(kg) | 5500 |

4. Producing and Packaging

From producing to delivery, we make every details very carefully to guarantee the good product quality and service to customers.

5. Certificates

6. FAQ

Q1: What are your main products ?

A: Our main products are the Prepress 4up and 8up Online/Offline Thermal CTP, CTCP, VLF CTP, Flexo CTP, Processor, Offset Plates, Offset Inks, Offset Printing Blankets, Postpress Packing Equipment and so on.Q2: Where is your factory ?

A: Our CTP machine factory is in Hangzhou city, which is about 1.5 hours by train from Shanghai. You are warmly welcome to visit our factory!Q3: Is there any certification for your CTP machine ?

A: Yes, all our CTP machines have been certified by SGS and CE.Q4: Can you also supply the Workflow and RIP ?

A: Yes, we can provide the Workflow Brainnew and RIP Compose V12.Q5: What about the Installation and After-sales technician support ?

A: Our engineer can go to help the installation and provide the necessary training. The buyer should take the round air plane tickets, service charge and the local accommodation cost. Any problems or questions, we will be at your disposal 7x24 hours. Among our large amount of CTP installations worldwide, there are also many end users (printers) who have purchased the CTP products from EcooGraphix China directly and EcooGraphix technical service team support these installations remotely with regular onsite visits.These end users printers all run the CTP systems with full satisfaction due to our robust quality, seamless remote service, thorough training and maintanence. If you are a printer who is considering purchasing directly from EcooGraphix China, there is no hassle on installations, training and after sales service. We guarantee your satisfaction.